SCR Exhaust Pipe Thermal Coupling Stress Analysis

INSULATION MATERIALS, SHIP EQUIPMENT & SHIP DESIGN.

Still deciding? Get samples first, Contact US !

View similar products

Products Detail

Comprehensive SCR Exhaust Pipe Thermal Coupling Stress Analysis

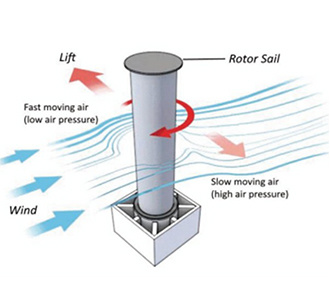

The SCR (Selective Catalytic Reduction) exhaust pipe plays a crucial role in reducing NOx emissions in modern engines. Thermal coupling between the exhaust pipe and adjacent components can induce significant stress due to rapid temperature changes during operation. Stress analysis of the SCR exhaust pipe is essential to ensure durability and prevent structural failure. Engineers use finite element analysis (FEA) to simulate thermal expansion, contraction, and material behavior under high temperatures. Proper material selection and optimized geometry reduce thermal stress concentration, ensuring reliable performance. Additionally, vibration damping and flexible couplings help mitigate stress from thermal cycles and mechanical loads. Accurate thermal coupling stress analysis improves component life, reduces maintenance costs, and enhances overall engine efficiency, making it a key focus in SCR exhaust system design.

SCR Exhaust Pipe Thermal Coupling Stress Analysis

INSULATION MATERIALS, SHIP EQUIPMENT & SHIP DESIGN.

Products Category

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!