PSA (Pressure Swing Adsorption)Nitrogen Generator

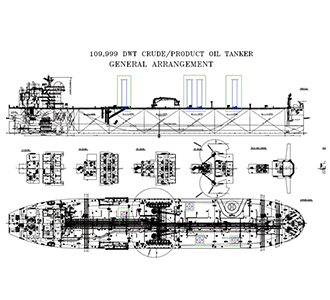

INSULATION MATERIALS, SHIP EQUIPMENT & SHIP DESIGN.

Still deciding? Get samples first, Contact US !

View similar products

Products Detail

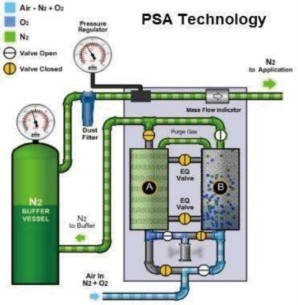

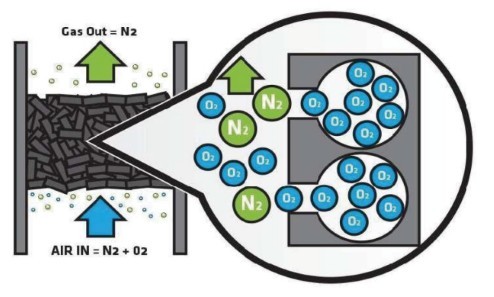

PSA nitrogen generator is a new gas separation technology, the principle is to use molecular sieve to different gas molecules adsorption performance differences and separate the gas mixture, it is air as raw material,using molecular sieve on nitrogen and oxygen selective adsorption performance to separate the nitrogen and oxygen in the air. Widely used in shipbuilding, chemical industry,electronics, metallurgy, machinery, food and other fields.

Adsorption Working Principle Diagram

Schematic Diagram of Displacement Operation

Business Scope: Design and approval, manufacturing, installation and commissioning, spare parts supply.

Production Capacity: Nitrogen production: 50-10000Nm'/h (It can be designed according to customer's demand).

Nitrogen Purity: ≤99.99%

Nitrogen Dew Point: -20~-65°C@ATM

Delivery Presusre : 7bar

Main Material: carbon steel

Certificates: ABS, DNVGL, KR, LR, CCS, NK, RINA, etc

Product Presentation

The working principle of PSA nitrogen generator is mainly divided into three stages: adsorption, pressure equalization and desorption.

Adsorption:

The dry air after impurity removal enters tank A from the bottom up, the pressure rises,the molecular sieve will separate the nitrogen molecules and oxygen molecules, and the qualified nitrogen is produced; A small amount of nitrogen enters tank B from the top down for purging, blowing away the oxygen molecules attached to the molecular sieve in tank B and discharging them from the oxygen-rich pipeline.

Pressure Equalization:

After the adsorption of molecular sieve in tank A is saturated, the air inlet and nitrogen outlet valves are closed, and the valves between tank A and tank B are opened for pressure balancing; No new gas enters or is produced in this process.

Desorption:

The air after drying and impurity removal enters the B tank from the bottom up, and the pressure rises. The molecular sieve separates the nitrogen and oxygen molecules, and the qualified nitrogen is produced. A small amount of nitrogen enters tank A from the top down for purge, blowing away the oxygen molecules attached to the molecular sieve in tank A and discharging them from the oxygen-rich pipeline.

Note: The process of adsorption and desorption occurs in cycles: tank A adsorption, tank B desorption;Tank A desorption, tank B adsorption.

PSA (Pressure Swing Adsorption)Nitrogen Generator

INSULATION MATERIALS, SHIP EQUIPMENT & SHIP DESIGN.

Products Category

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!